July 01, 2022

Rebuilding a HIBLOW Pump: Should I Only Replace the Diaphragms?

Why installing a full rebuild kit is critical to pump performance and longevity.

It is inevitable that at some point in time your HIBLOW linear air pump will stop running. Most often that means that the diaphragms have ruptured, which activates the safety mechanism cutting power to the pump. This ensures that the magnetic rod does not tear up the inside of the pump – making it irreparable.

One of the advantages of choosing HIBLOW is that the pump can be rebuilt 2 times at a fraction of the cost of a brand-new pump. You may notice that there are different rebuild kit options on the market, most notably buying a full rebuild kit or the diaphragms only kit. It is HIBLOW’s strong recommendation to buy the full rebuild kit.

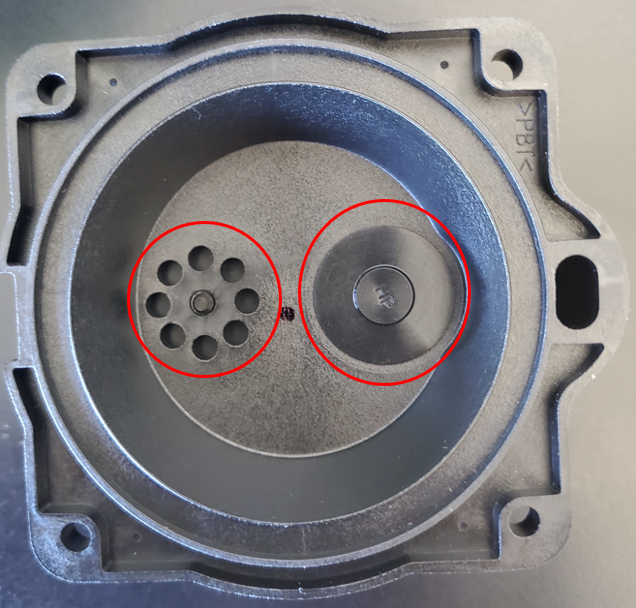

There are only a few moving components in a HIBLOW pump. Connected to the oscillating magnetic rod, the diaphragms wear and eventually rupture. The umbrella valves that are located within the casing blocks open/ close 60 times per second and wear over time. If the valves wear too much, the pump is not able to pressurize the air and your system’s performance will suffer. The degradation of the valves is gradual, so the loss in pressure may not be noticed for quite some time. It is prudent to replace the casing blocks and the diaphragms at the same time.

HIBLOW also offers a couple other rebuild kit options that include gaskets. The black base gasket seals the upper and lower housing. With years of use or in hot climates, the gasket can become brittle, and air can seep through causing a loss in pressure. The filter cover gasket can also wear. HIBLOW recommends checking the gaskets before rebuilding the pump.

Check out our support page or YouTube for videos on how to install a full rebuild kit for your HP or XP Series Linear Air Pump!

If you have any further questions about the maintenance or repair of your pump, please do not hesitate to reach out by phone: 734-944-5032, or email: info@hiblow-usa.com